Our engineering staff and experienced shop personnel possess all of the necessary skills and tools to construct world class plastic injection molds. We have equipped our employees with the highest quality equipment and tools to ensure your tooling is built to highest possible quality standards. Tri Tech Tooling can also provide the lead times required to ensure your product reaches the marketplace as fast as possible.

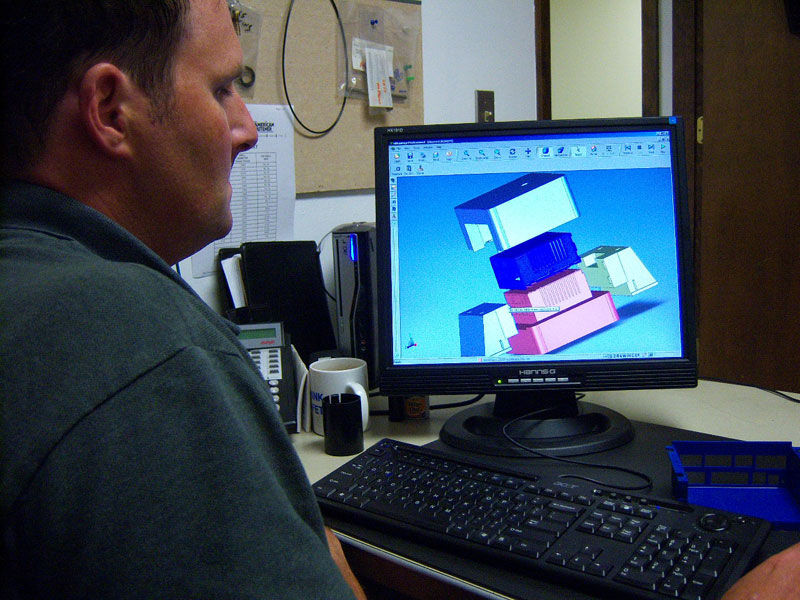

With the use of state of the art mold design software, Tri Tech Tooling is able to rapidly produce 3D mold designs. Various add-on design modules allow for quick and easy changes to the mold design during the entire mold build process. Validation and simulation tools allow for a robust and error free design.

Tri Tech Tooling understands the importance of a quick turnaround when it comes to changing or repairing your production tooling. By using of all of the resources available to us, Tri Tech Tooling is able to process engineering changes and mold repairs in a very efficient manner. All data relating to every mold Tri Tech Tooling has built is readily available to make the necessary engineering changes or mold repairs to all of the injection molds we have built in the past.

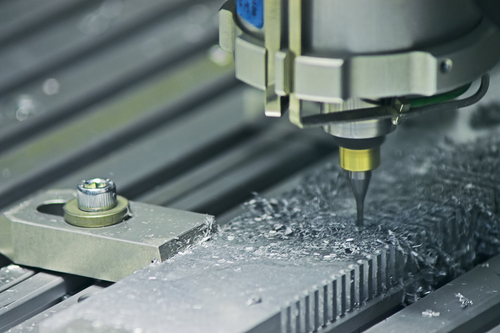

Tri Tech Tooling has equipped its manufacturing team with a wide variety of vertical CNC machining centers. Our skilled staff of programmers and operators can efficiently process various machining projects with the use of all of the available machines and tooling in our facility. Our focus on accuracy, efficiency and surface finish allows us to provide our customers with high quality CNC machining.

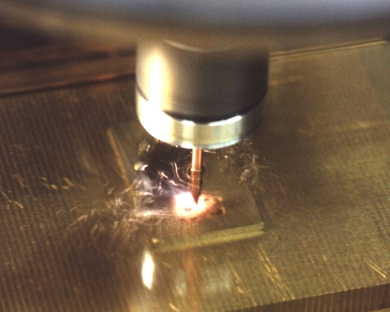

When cavity and core CNC machining becomes too inefficient, we turn to our wide variety of CNC EDM machining centers. Efficient production of graphite electrodes in our dedicated high performance CNC machines allows deep and/or intricate detail to be produced whenever the need arises. Our focus on accuracy, efficiency and surface finish allows us to provide our customers with high quality EDM machining.